Who we are

Led by the second

generation of the

owner family

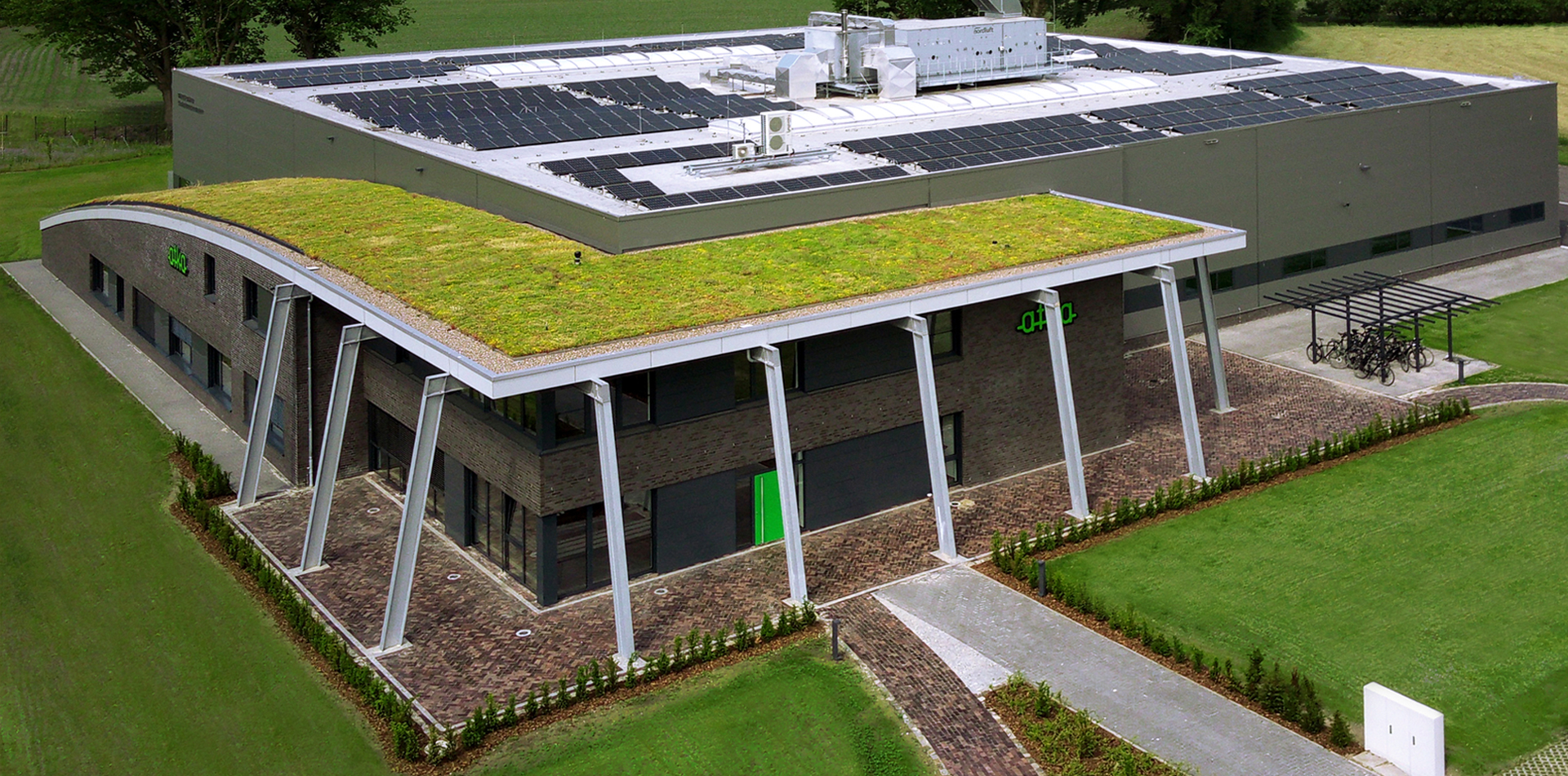

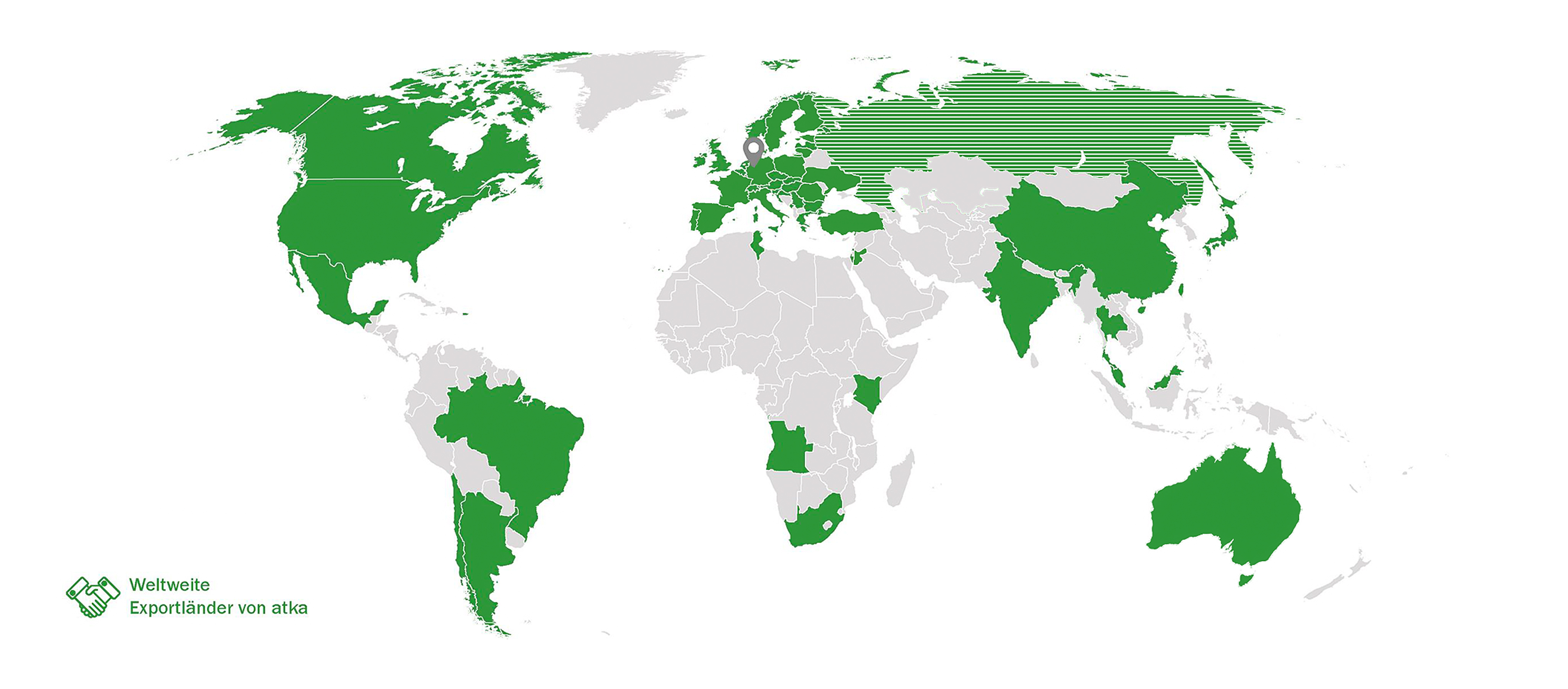

For over 40 years, atka Kunststoffverarbeitung GmbH has been a reliable partner in the development and manufacture of plastic products as well as the corresponding tool moulds and automation devices. Together with our over 100 employees, we produce plastic components weighing between 0.03 g and 9.8 kg for our global customers at our state-of-the-art site in Lohne.

The formation of the company in 1981 laid the foundation for successful growth. For instance, our company has already supplied 3,000 different components for all manner of different industries, and everything – from development and design through to tool mould construction, production and automation – comes from a single source. Our cutting-edge fleet of machinery and large storage space mean that we can supply our customers reliably and flexibly even when times are fraught.