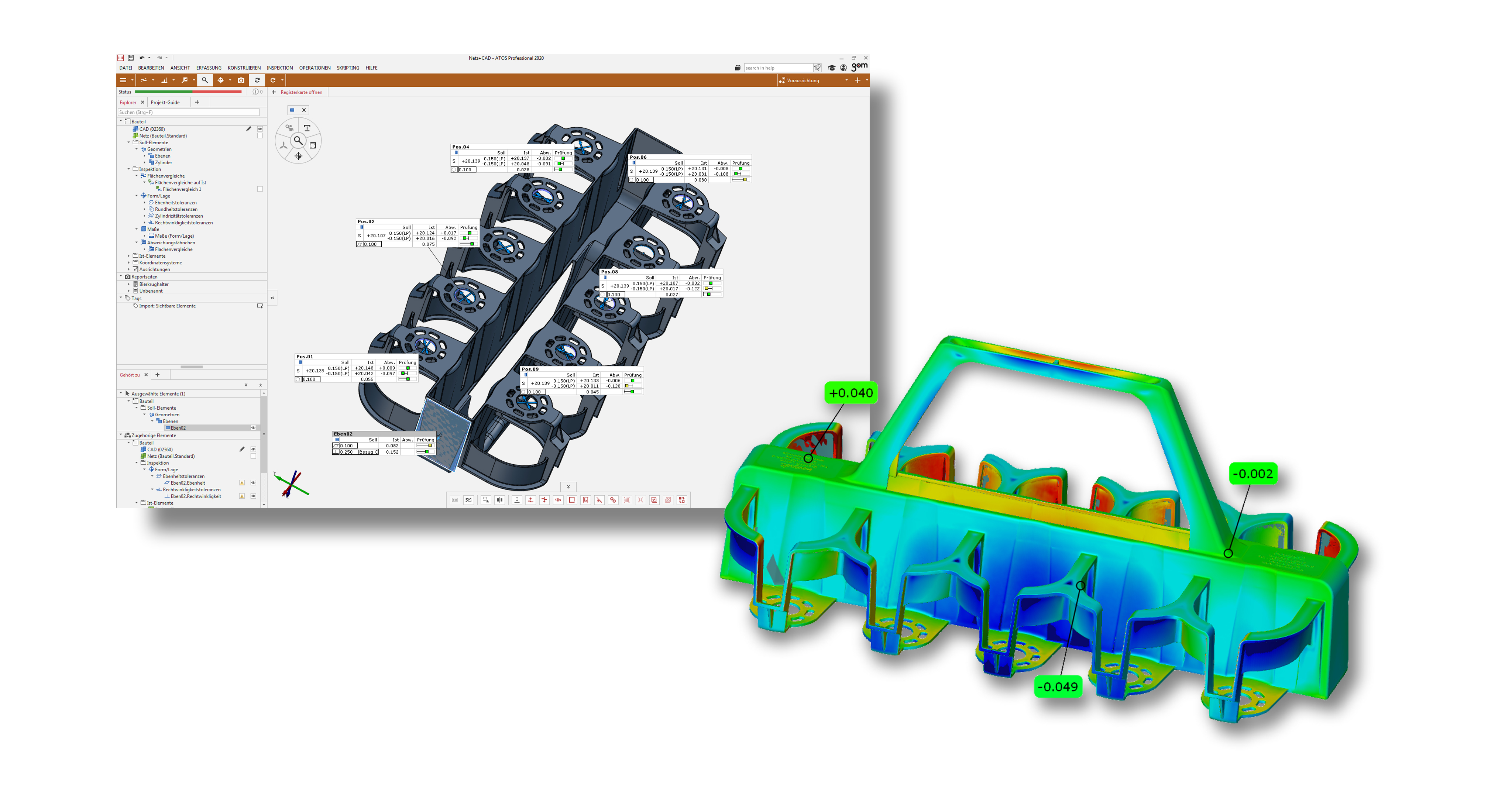

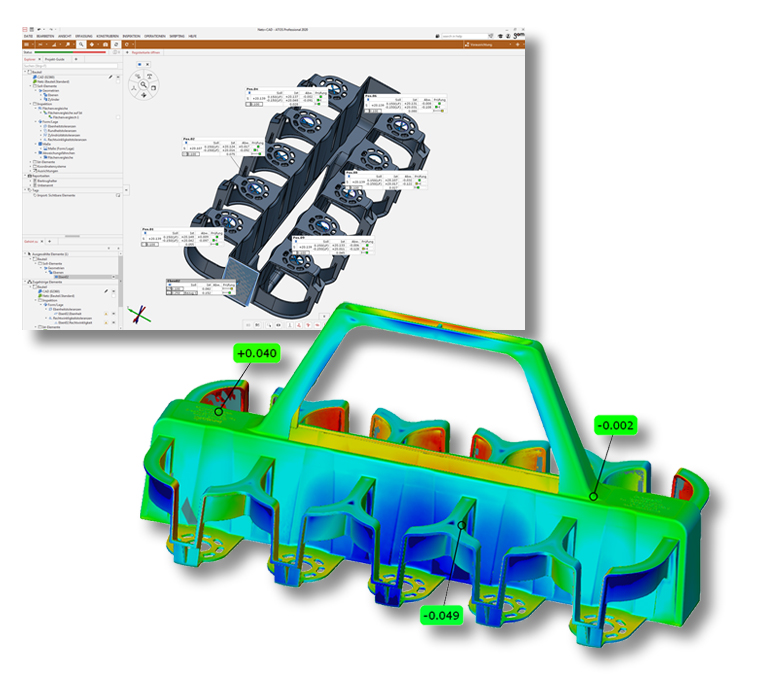

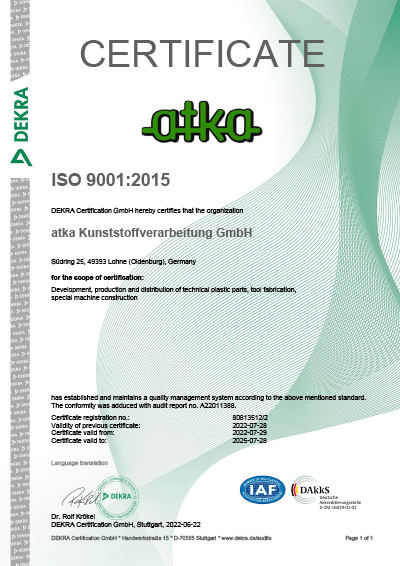

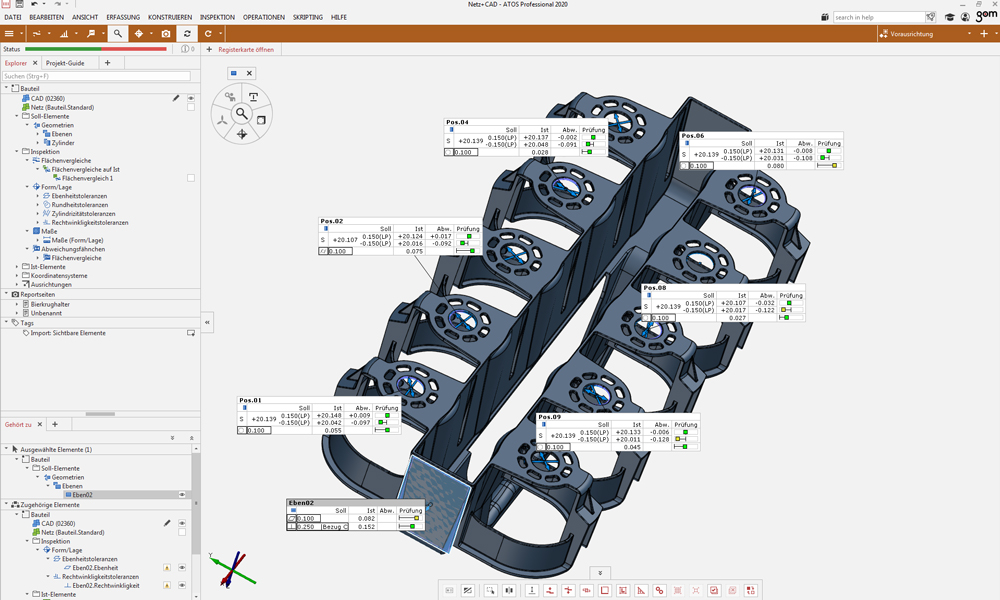

Ensuring safety and quality is a key tenet of our product and corporate philosophy. Throughout the production process – right through to the final checks, storage and delivery of our products – we use effective testing and inspection mechanisms that guarantee consistently high quality for our customers. We monitor, control and log all work steps precisely, as demonstrated by our certification in accordance with ISO 14001:2015 and ISO 9001:2015.